Euromats

- Dimensions:

113cm × 244cm - Thickness:

1.27cm - Weight:

36kg

We are now offering Euromats, which are aimed at a variety of industries and applications. Their unique self cleaning gripped surface is aimed at dispelling mud but will still give grip to vehicles or pedestrians as they cross the mat.

Suitable for:

Loading Spec:

Price per board: POA.

Unbreakable to over 150* tonnes, TuffTrak®, our temporary roadway, is the ultimate heavy duty panel providing temporary road ways and work areas for very heavy plant, machinery and multiple vehicles.

Suitable for:

Loading Spec:

Price per square metre: POA.

We are now offering Trakmats, which are aimed at a variety of industries and applications. Their unique self cleaning gripped surface is aimed at dispelling mud but will still give grip to vehicles or pedestrians as they cross the mat.

Suitable for:

Loading Spec:

Price per board: POA.

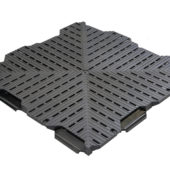

Diamond Track is a temporary flooring solution for both indoor and outdoor use. It protects your valuable surfaces and areas of high pedestrian traffic from unsightly wear.

Suitable for:

Loading Spec:

Price per tile: £55.97

Geogrid is a high quality heavy duty ground reinforcement tile and cellular paving system and is made of recycled polyethylene to increase robustness and strength.

Suitable for:

Loading Spec:

Price per square metre: £22.20

Geogrid is a high quality heavy duty ground reinforcement tile and cellular paving system and is made of recycled polyethylene to increase robustness and strength.

Suitable for:

Loading Spec:

Price per square metre: £22.79